| 1. | Conductor | Stranded plain annealed copper wires as per IEC 60228, Class 2 |

| 2. | Conductor screen | Semiconducting layer compound |

| 3. | Insulation [T] | XLPE as per IEC 60092-351 |

| 4. | Insulation screen | Non-metallic part: semiconducting layer compound Metallic part: copper tape A suitable separator tape(s) may be applied over the metallic jacket |

| 5. | Cabling | Three metallic wrapped conductors shall be cabled Flame retardant & non-hygrocopic fillers may be used Suitable tape(s) may be applied on the cabled core A filler may be applied to obtain a circular cable |

| 6. | Inner covering [I] | SHF 1 as per IEC 60092-359 |

| 7. | Armour [O] | Braid of tinned annealed copper wire Coverage density: min. 90% |

| 8. | Sheath [I] | SHF 1 as per IEC 60092-359 Sheath color: Red |

| 9. | Identification | Color tape shall be inserted under metallic screen 3C - Black, Brown, Grey |

| NOTE : The order color of sheath and insulation may be applicable when purchaser required. | ||

APPLICATION STANDARD

| 1. | Design guide | : IEC 60092-350, IEC 60092-353 & IEC 60092-354 |

| 2. | Insulation material | : IEC 60092-360, XLPE |

| 3. | Sheath material | : IEC 60092-360, SHF 1, SHF 2, ST2 |

| 4. | Flame retardant | : IEC 60332-1 &IEC 60332-3 Category A |

| 5. | Halogen content | : IEC 60754-1, 0.5 %↓ |

| 6. | Smoke emission | : IEC 61034, 60% ↑ |

| 7. | Cold bend/impact | : CSA 22.2 No.0.3 (-40?C / -35?C) |

| 8. | Max. rated conductor temp. | : 900C |

CABLE DESIGNATION

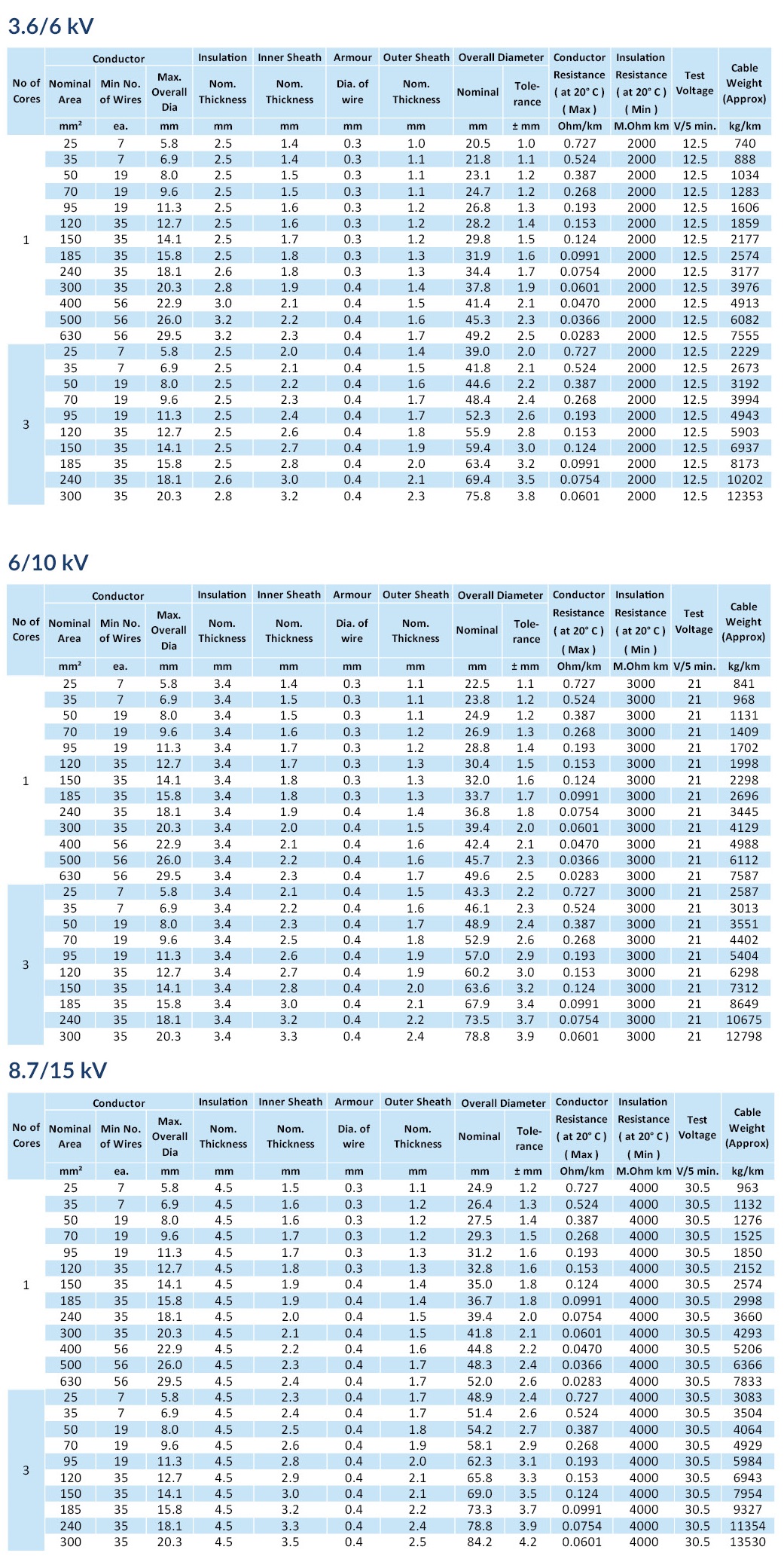

3.6/6 , 6/10, 8.75/15 kV TIOI (CU/XLPE/CTS/SHF1/TCWB/SHF1)

3.6/6 , 6/10, 8.75/15 kV TICI (CU/XLPE/CTS/SHF1/GSWB/SHF1)

3.6/6 , 6/10, 8.75/15 kV TIOI (CU/XLPE/CTS/SHF2/TCWB/SHF2)

3.6/6 , 6/10, 8.75/15 kV TUCU (CU/XLPE/CTS/SHF2/GSWB/SHF2)

3.6/6 , 6/10, 8.75/15 kV (CU/XLPE/CTS/ST2/GSWB/ST2)